Making the Doodle Table -Part 1

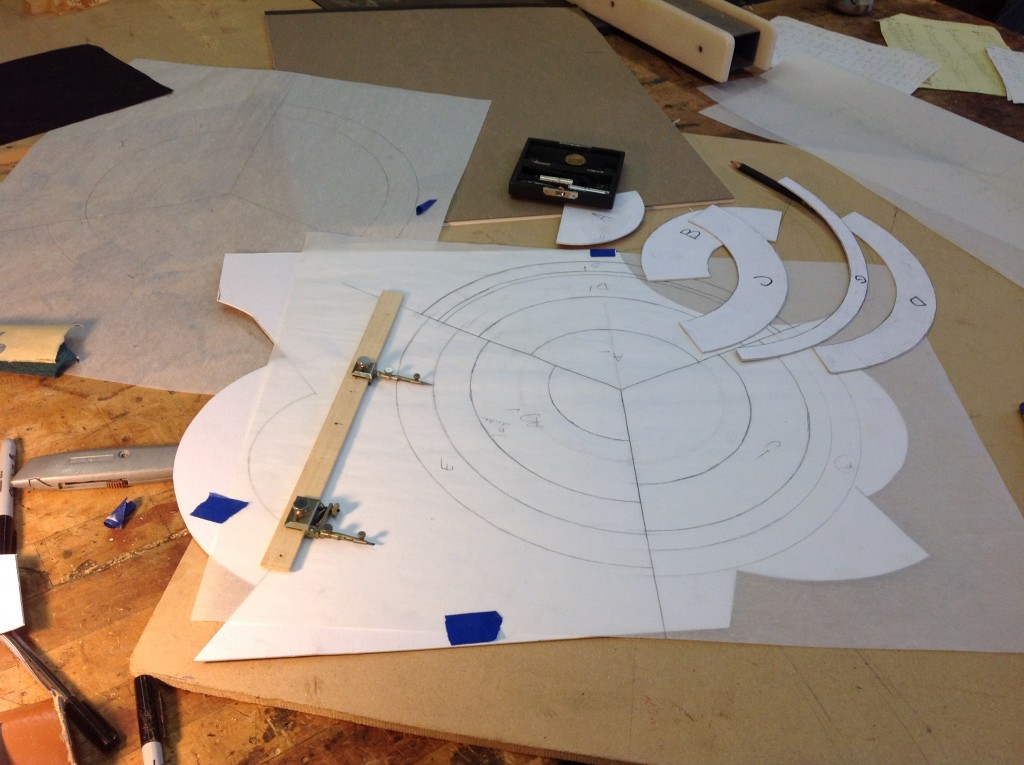

Sketches, scale models, full sized drawings and sometimes full size mockups are always the starting points.

Sketches, scale models, full sized drawings and sometimes full size mockups are always the starting points.

After the Full sized drawing was finalized the “Egg” was cut out from many layers of maple. The curved pieces were made from templates that were calculated from the full sized drawing.

After the maple was cut out with the templates Their edges were beveled on the bandsaw to reduce the amount of roughing out on the lathe.

With the help of a very nice Oneway lathe, I was able to turn the Egg shape in two sessions. The sections had to be turned in parts because I didn’t have a way to get deep into the inside to turn it, so I turned the inside in sections then glued them up and turned the entire outside when it was all one piece.

Once the turning was done I started puzzling out how to get the legs to fit into it. I made a small mock up to help me figure out how I need to carve the egg to accept the legs and aprons.

The whole idea of a solid wood “egg” shape set tightly between the walnut legs created a complication in design. Stacked wood will expand and contract a lot, so this “Egg” will have the most movement top to bottom. To compensate for this I decided to attach the “Egg” at the top and let it expand and contract due to seasonal humidity changes below that. To Keep the legs from getting pushed apart my this movement I created grooves for the legs to float in.

Leave a Reply

You must be logged in to post a comment.